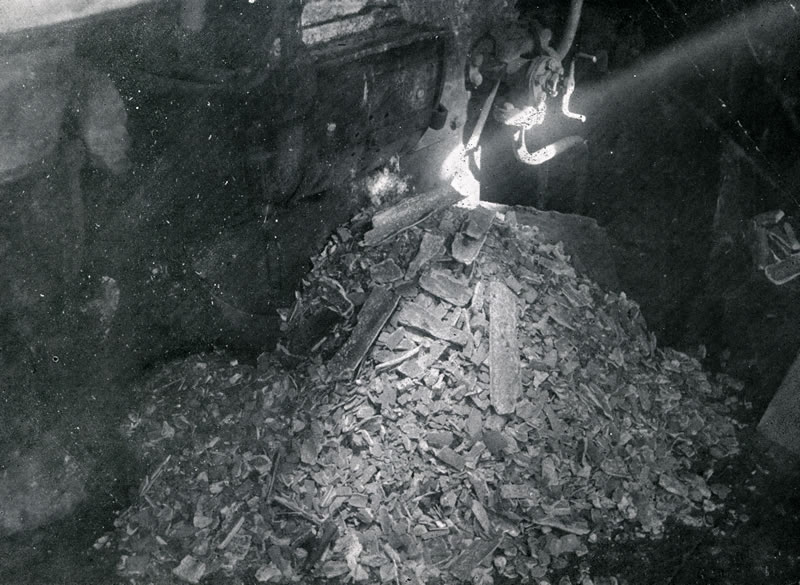

Photo showing scale lying in the bottom of the boiler after falling off the tubes. The heap of scale extended along the bottom the whole length of the tubes.

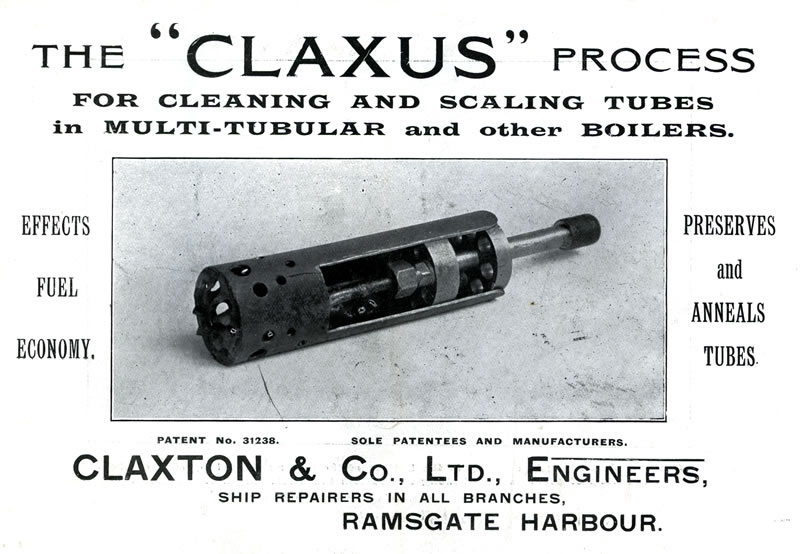

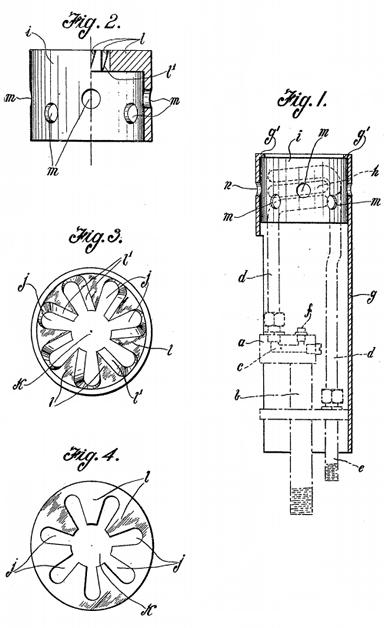

The question will naturally arise in the mind of any responsible engineer as to whether there is any prospect of damaging the boiler.

The results were carefully watched when the Inventors were making their experiments, and since then thousands of tubes on various vessels belonging to different ports have been cleaned. In some cases the tubes were over twenty years old.

In no case has there been any damage caused by the process. On the contrary, the passage of the tool heats the tube to a moderate temperature; never more than a very dull red heat, though usually the scale flies off at a "black heat".

The tube is allowed to cool out naturally, so the metal is annealed, and its structure returned to its original condition.

Thus, in addition to the great saving in fuel effected, the tubes are left in a better condition than before being cleaned.

Photo showing specimens of scale rernoved from a boiler. Note the 2ft rule showing size of pieces.

It is a matter of great importance that this tool is "Fool Proof".

It can generate the necessary heat to clean the tubes, but not sufficient to over-heat or damage them.

An example of the value of the process is as follows:

A small trawler, with ordinary marine type boiler, making short trips, used 11 tons of coal per week when new. It was impossible to clean the tubes properly by the ordinary means, and the consumption gradually rose to 17 tons per week. After cleaning with our process, the consumption returned to 11 tons per week.

Of course the economy effected varies with the condition of the tubes before cleaning, but the result is always substantial.

It is not uncommon for a two-furnace boiler to yield 8 to 10 cwt. of scale.

Photo showing heap of scale in stockhold as removed from a trawler's boiler. Boiler has 2 furnaces, 80 tubes. Weight of scale - 8 cwt.